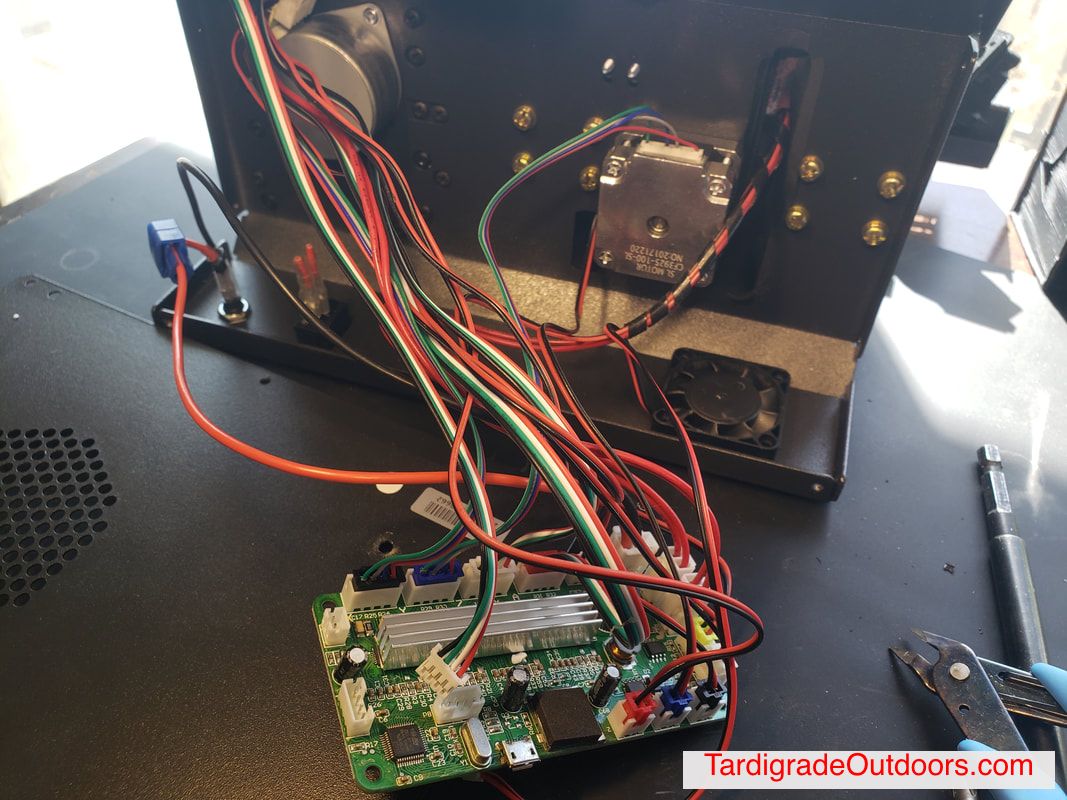

* replacing the stock M200_V2-MAINBOARD with SKR 1.4 board with 2208 stepper motor drivers.

* adding a controllable parts cooling fan.

* adding Octoprint via GPIO

* adding 2 channel wifi power control with additional local button control.

* adding local buck power converter to power the Raspberry Pi

* adding local electronics fan temperature controller and an additional electronics cooling fan.

* adding daytime/nighttime IR-Cut camera.

* adding remote monitoring via Octoeverywhere and Printoid.

$155 for the two printers.

$45 for a RPI 3B+

$0 for the RPI 3B+ that I already had

$35 for a SKR 1.4

$0 for a SKR that I already had

$25 for 2208 stepper motor drivers

$0 for for 2208 stepper motor drivers that I already had

$6 for two untested temperature controlled fan controllers

$40 for two IR-Cut cameras (in a separate post)

$5 for two 30mm axial parts cooling fans (in a separate post)

$5 for two 40mm axial electronics cooling fans

$14 for two untested 2-channel wifi controllers

$10 for various buck converters, USB solder ends, etc.

So, about $350 for the two machines.

I would also have to design mounts for the electronics, solder components and test some new-to-me stuff. I'd also need to compile new firmware.

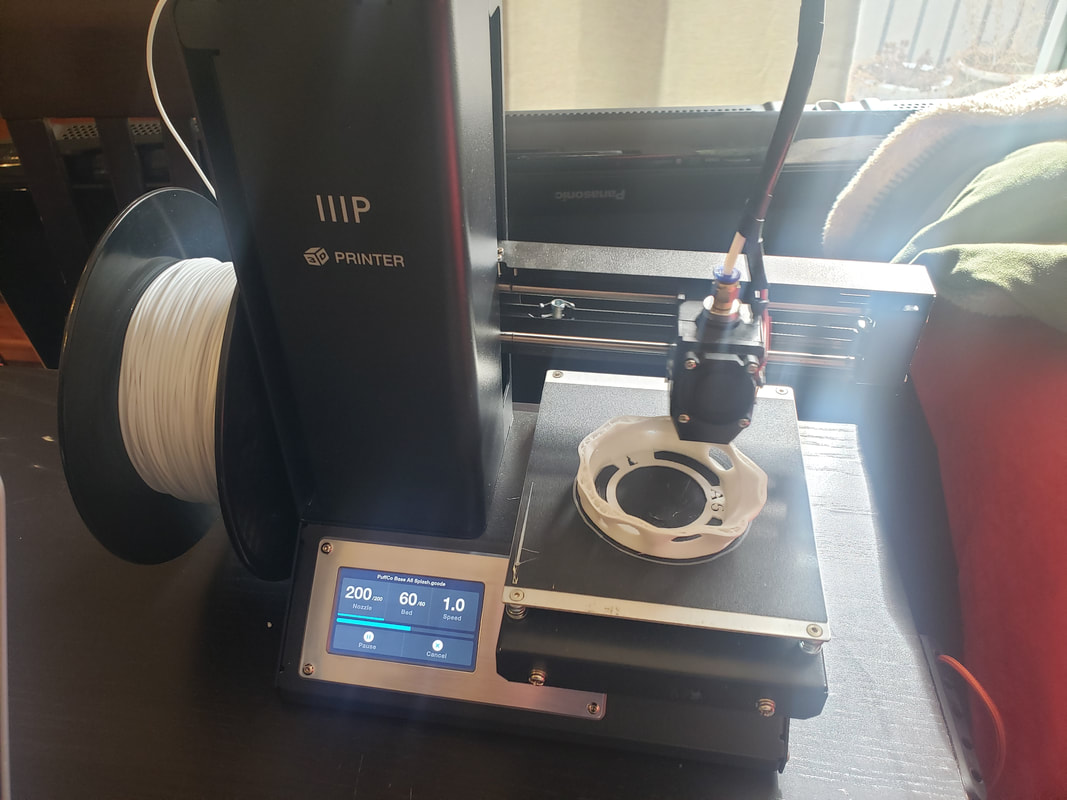

The 3D files can be found on my Thingiverse post: https://www.thingiverse.com/thing:4871193

Please note that these files are too large to be printed on a Mini.

* Be well-versed with 3D printing

* Have intimate knowledge of how to customize a 3D printer

* Be experienced with soldering and electronics; be already equipped to solder and have electrical connectors like Duponts and whatnot.

* Know VSCode and how to manipulate firmware

* Have a quality set of tools and parts for 3D printers. Aside from reusing the stock black screws, I mostly used 3mm screws, maybe 4mm, 6mm, and 8mm in length. Heck the fan screws might be 12mm.

* Not be entirely sane

Overview

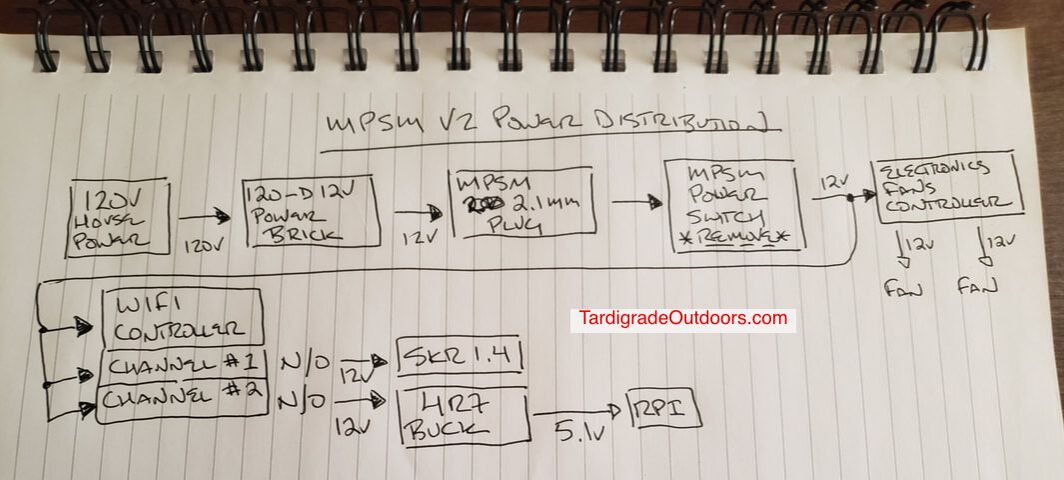

I started with the basics, learning everything I could about the machines, including reading and watching several upgrade tutorials. I went through all the literature I could find. I tested my current machines to make sure the mechanicals were sound. Then, I sketched out a plan on paper of what I wanted and how I would connect everything. I started searching for components that would get me the solutions that I wanted. Some of these I had not heard of before, so I knew integration might be risky. I made a list of what I needed to buy and assembled my parts. Then I wondered, Would they all fit inside the existing electronics case?

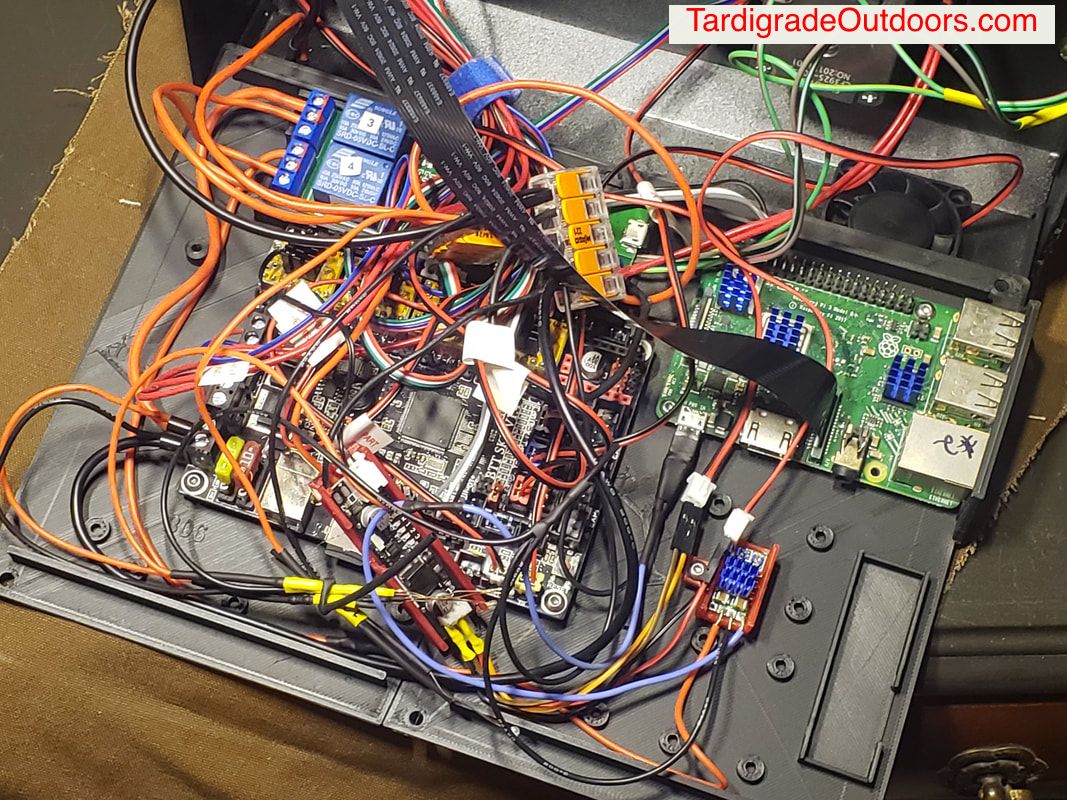

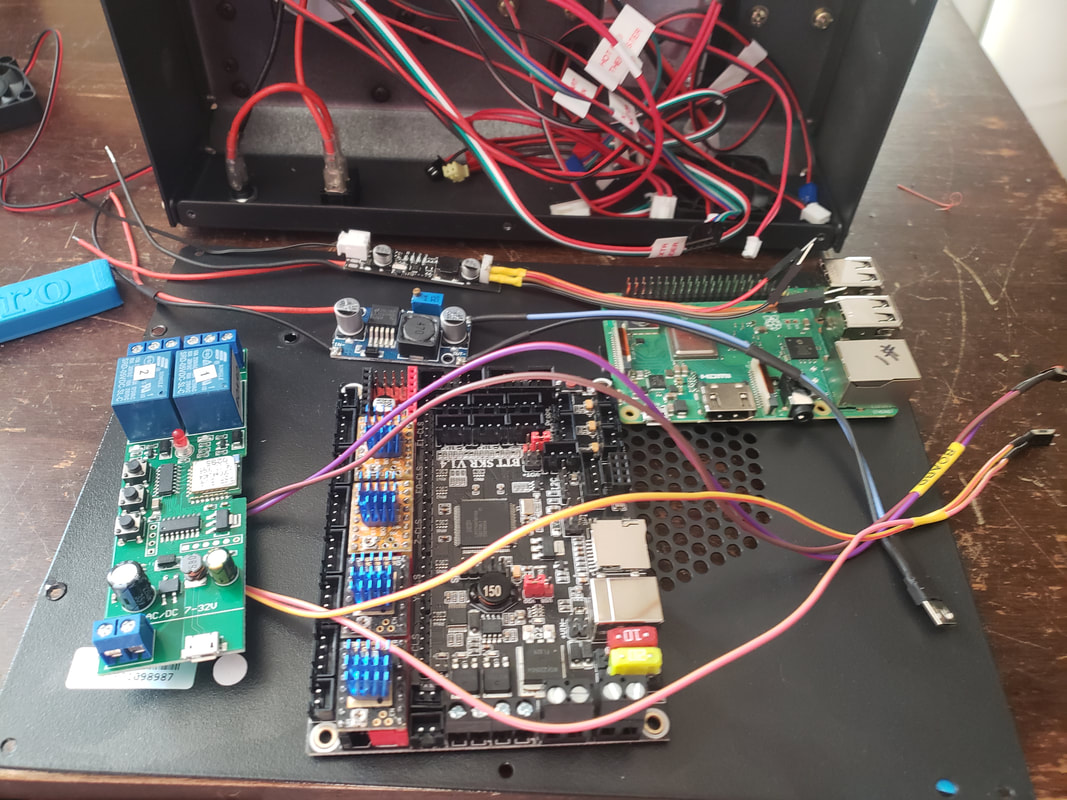

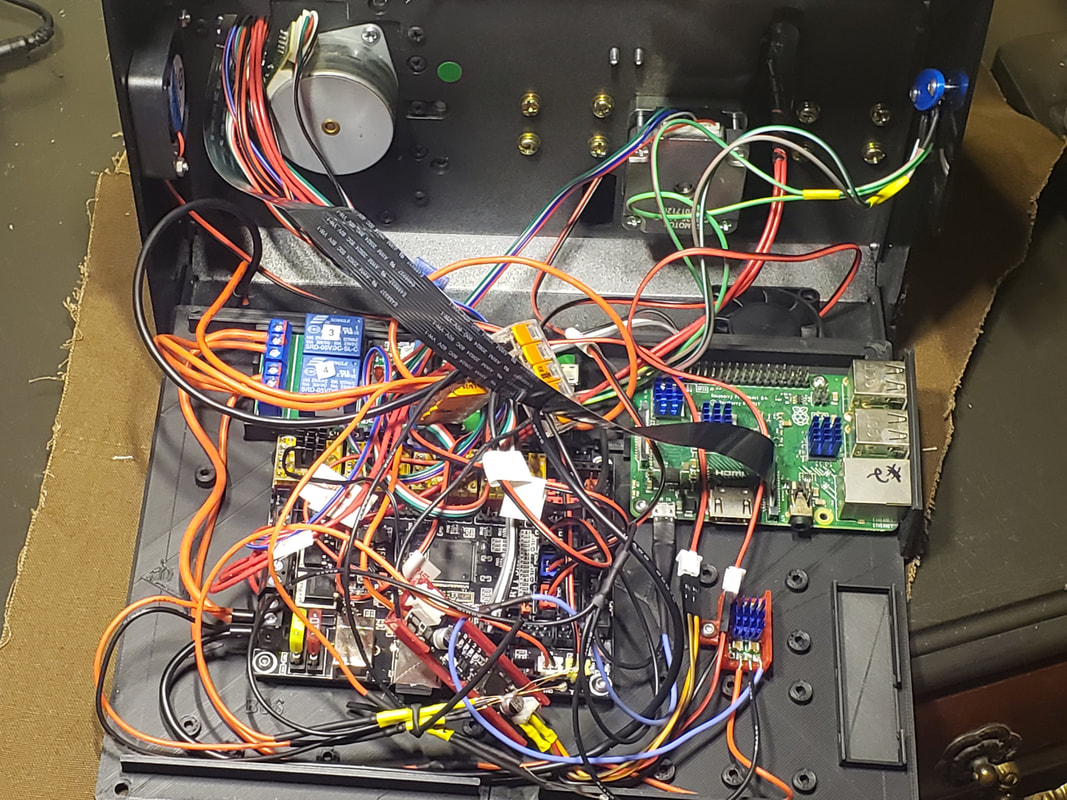

I set the SKR 1.4, RPI, wifi controller, fans controller, and buck converter on top of the Mini's bottom cover. I knew I wouldn't be reusing the posts, so I wiggled them back and forth until they broke loose. I arranged the electronics, took some measurements and made a new set of plates that mounted everything. This new plate could sit on the old bottom cover.

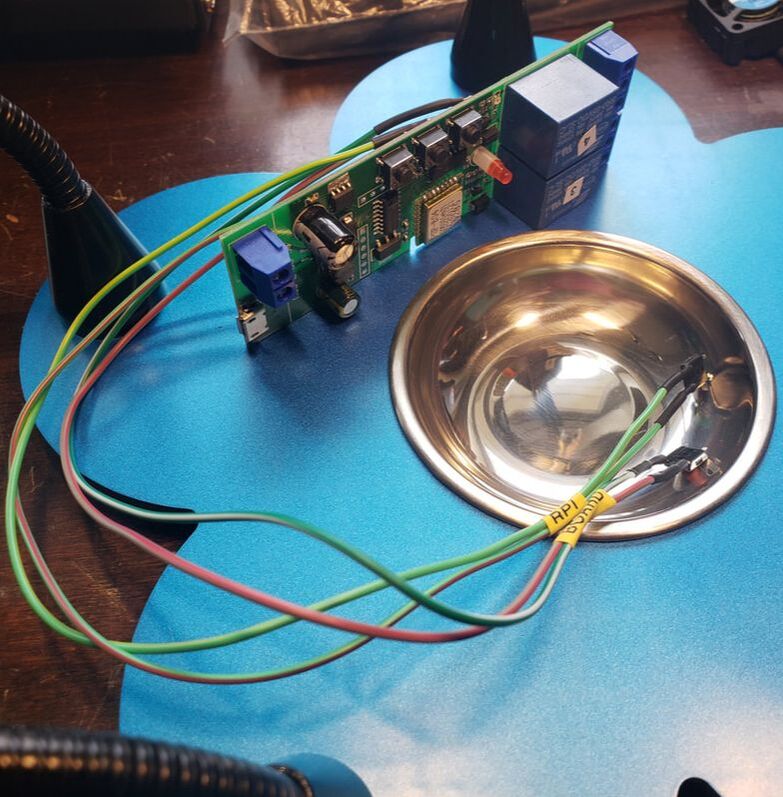

I wired up the wifi controllers, buck converters and fan controllers and tested them. I'll touch on each of them in this post.

I'm going to divide up this post into the major parts:

* Power wiring

* Electronics enclosure fan temperature controller and fans

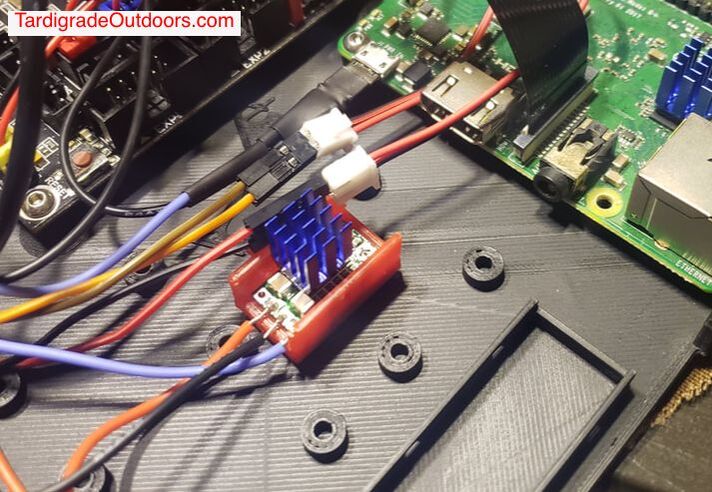

* Wifi controller

* Buck converter for the RPI

* SKR 1.4 & 2208 firmware

* Serial connection between the SKR 1.4 and RPI

* Future work

I hope I worded that right.

Use a multitap to connect it to incoming power. I used standard DuPont connectors and flexible silicone insulated wires to connect to the existing fan connectors. The programming instructions are insane, so I generously included some that are slightly less cryptic. Download the file, "fans_controllers_instructions.pdf". I set mine to "2, 2, and 2" because it seemed reasonable, YMMV. The controller snaps into part "B11 MPSM Ele Fan Control Skid", or the one with mounting holes, or the East skid. They're designed to be filed on the inside for custom mounting tension. Place it where you can get to it while printing for adjustment. Good luck.

| fans_controllers_instructions.pdf |

I wanted buttons that I could mount on the outside case for local, manual control, so I soldered on a set. I suggest these wires and these buttons (3 mm x 3.5mm x 2mm or 4mm x 4mm x 2 mm will fit fine). I wired the leads to the bottom, as shown. Then, I tested: https://imgur.com/a/TqisBuo. The momentary contact buttons are mounted on the "East Cover" and secured with a "ButtonsLED" mount and 3mm x 4mm long screws. I wired it all via the above sketch. The power to the motherboard should use heavier wires, such as these 18ga wires.

I always provide power to my RPIs via the USB connectors, even if I'm using soldered USB connectors, which I actually prefer. Powering via GPIO bypasses the power regulation and fuse protection and why take that chance when we're soldering anyways? Here is a link to solderable Micro USB connector and USB-C connectors that I have used.

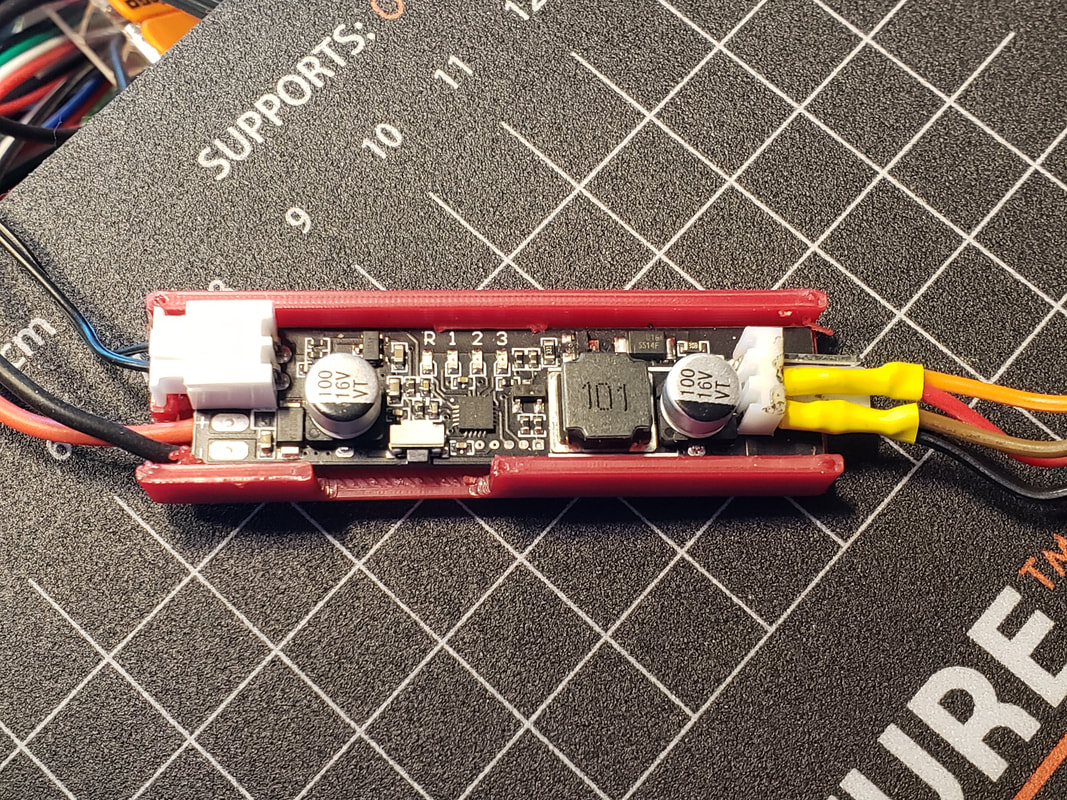

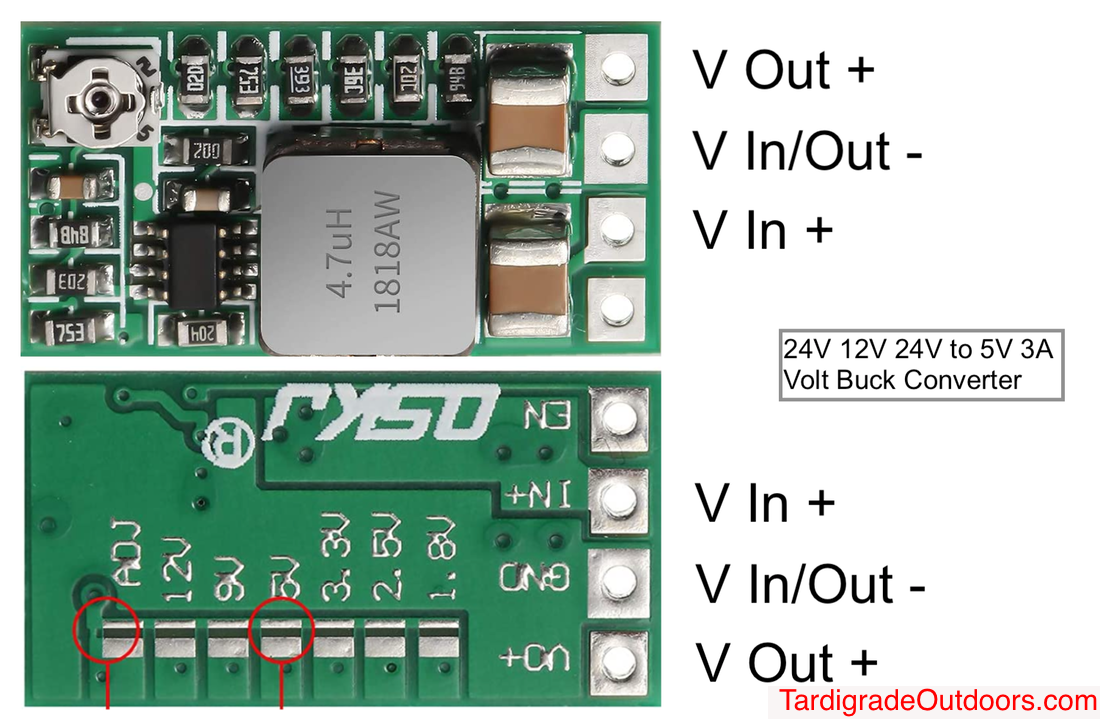

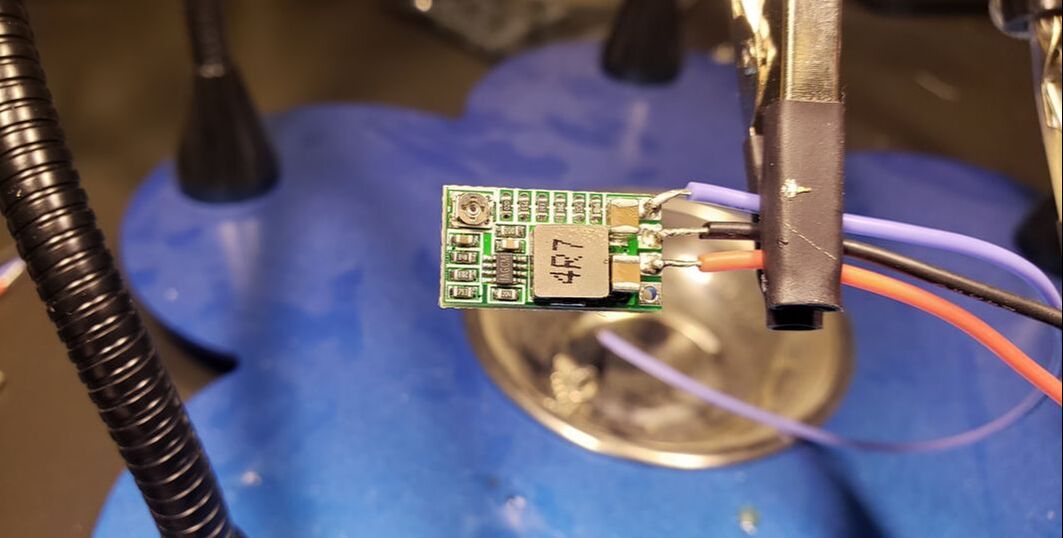

I reduced the voltage coming from the controller to 5V for the RPI using this buck converter. But, beware, the connections are mislabeled! This should help:

Wiring up and mounting the SKR 1.4 is not a big deal. Same with the 2208 drivers. Follow the manufacturer's instructions and use your vast experience and you'll be fine. You probably already know this.

Compiling firmware is complicated and I hope to share some helpful information on a later post. One should already be familiar with compiling firmware before attempting this. However, I have included a txt here on my changes for reference. YMMV.

| the_firmware_changes_i_made_skr1.4_2208_mpsm_v2.txt |

Everything should be mounted to the skids and wired up at this point. I've detailed how to do the serial connect in another blog post.

The bottom skids have little walls to keep the wiring off of the metal bottom of the printer. I've included wire management options. Don't forget to monitor and setup the fans controller after the printer has been running for a while.

RSS Feed

RSS Feed