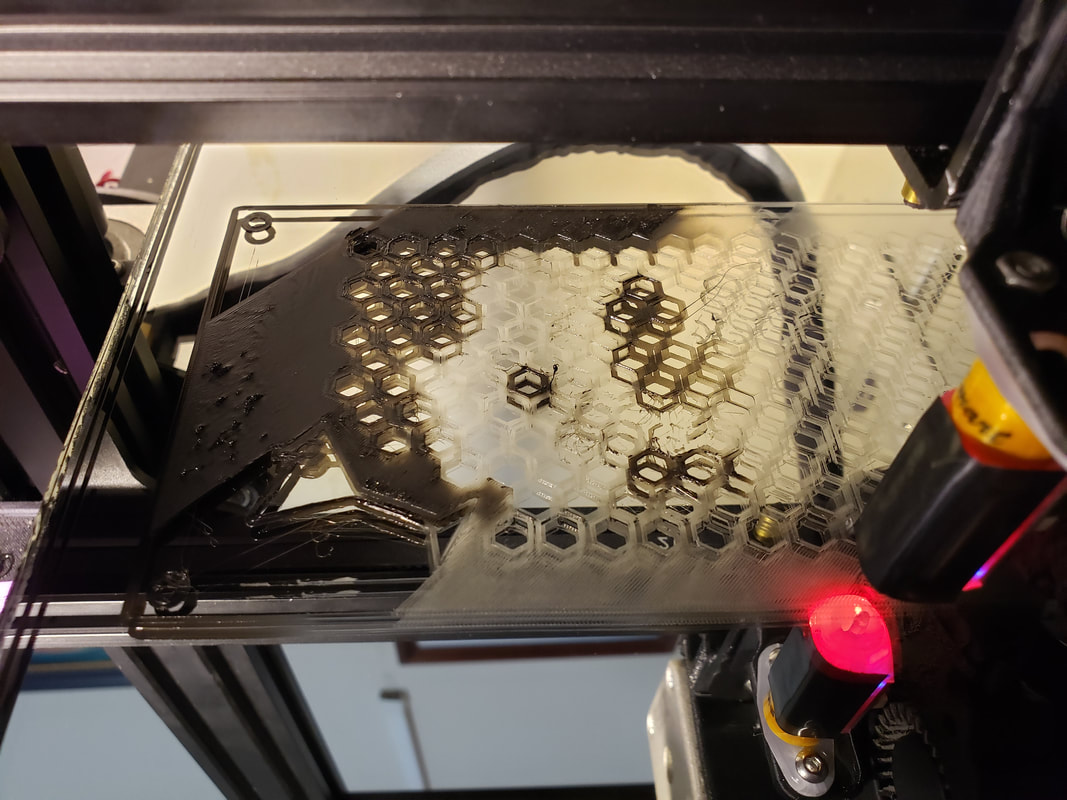

As the original joystick on my Quest 2 controller broke within 8 months, I wanted a replacement thumbstick to last a very long time. After 11 revisions to dial in the fit, I got it right. Earlier versions became loose after a few months, but this is have been great! As I still couldn't find them elsewhere, I made them available for others. I've sold over one hundred so far:

If you buy any, let me know how they work for you! I put a lot of effort into these, and even been making the thumbsticks in a variety of colors.

RSS Feed

RSS Feed